LVDT Transducers (Linear Variable Differential Transformer)

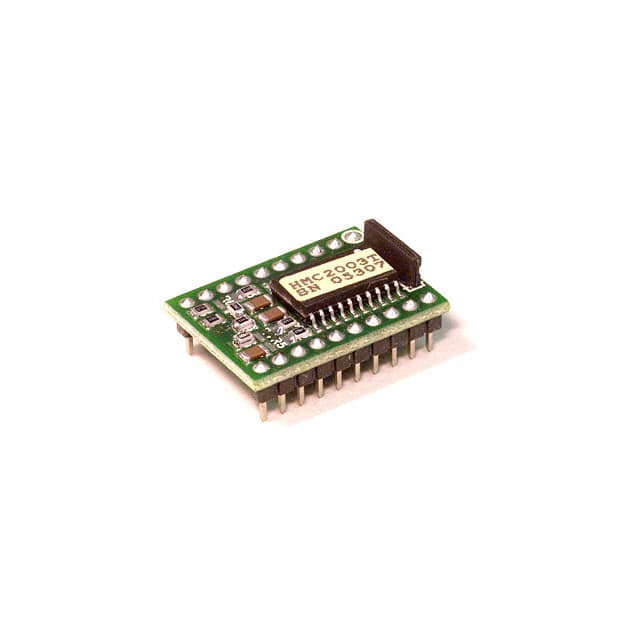

Magnetic Sensors - Compass, Magnetic Field (Modules)

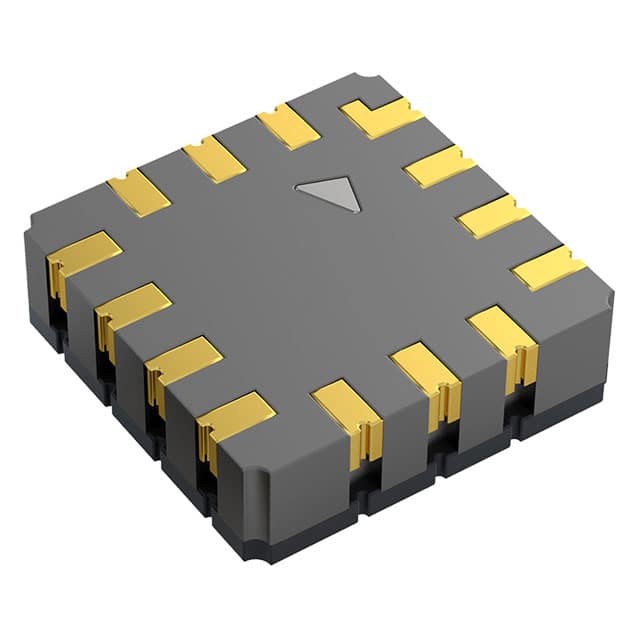

Magnetic Sensors - Linear, Compass (ICs)

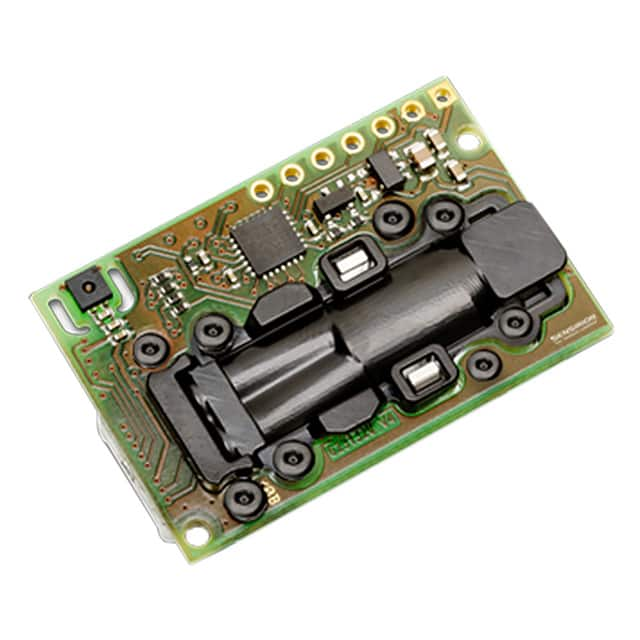

Magnetic Sensors - Position, Proximity, Speed (Modules) - Industrial

Magnetic Sensors - Position, Proximity, Speed (Modules)

Magnetic Sensors - Switches (Solid State)

Magnets - Multi Purpose

Magnets - Sensor Matched

Motion Sensors - Accelerometers

Motion Sensors - Gyroscopes

Motion Sensors - IMUs (Inertial Measurement Units)

Motion Sensors - Inclinometers

Optical Sensors - Ambient Light, IR, UV Sensors

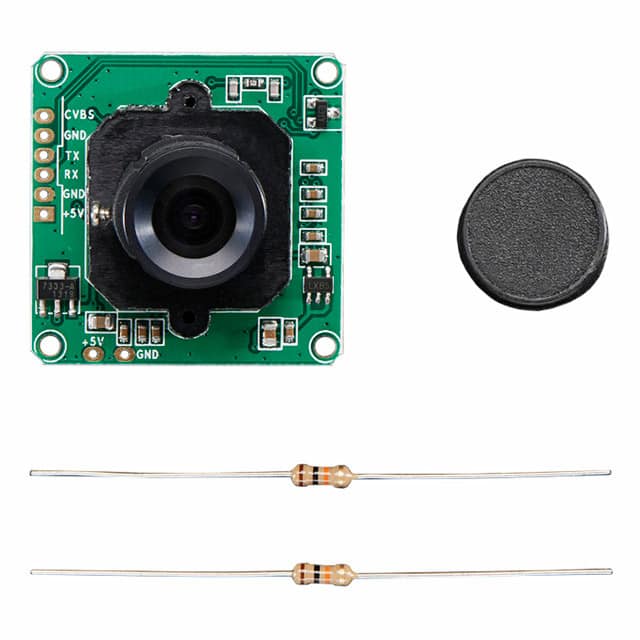

Optical Sensors - Camera Modules

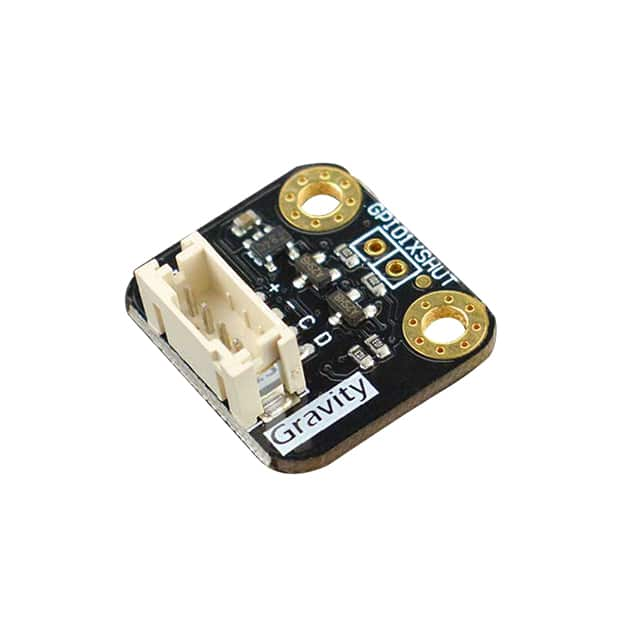

Optical Sensors - Distance Measuring

Optical Sensors - Image Sensors, Camera

Optical Sensors - Photo Detectors - CdS Cells

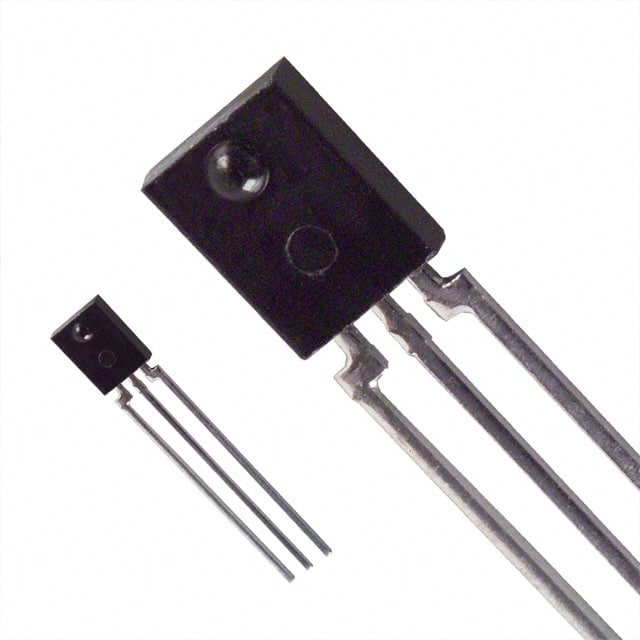

Optical Sensors - Photo Detectors - Logic Output

Optical Sensors - Photo Detectors - Remote Receiver

Optical Sensors - Ambient Light, IR, UV Sensors

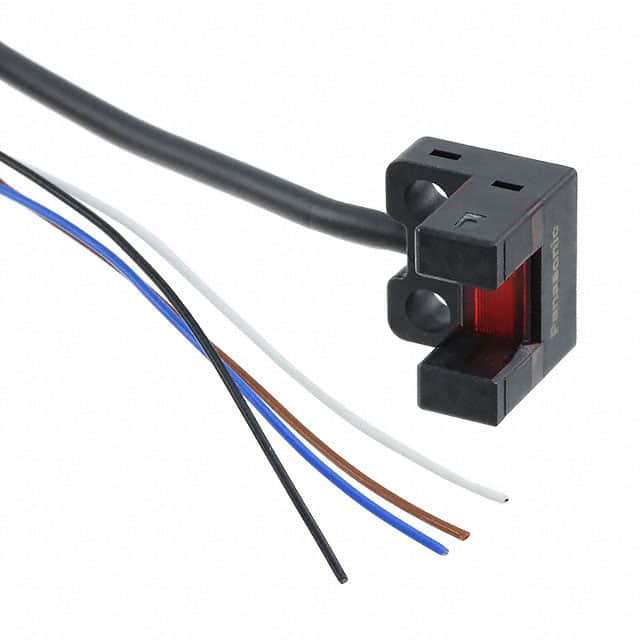

Optical Sensors - Photoelectric, Industrial

Optical Sensors - Photo Detectors - CdS Cells

Optical Sensors - Photointerrupters - Slot Type - Transistor Output

Optical Sensors - Photonics - Counters, Detectors, SPCM (Single Photon Counting Module)

Optical Sensors - Phototransistors

Optical Sensors - Reflective - Analog Output

Optical Sensors - Reflective - Logic Output

Position Sensors - Angle, Linear Position Measuring

Sensor Cable - Accessories

Sensor Cable - Assemblies

Sensor Interface - Junction Blocks

Temperature Sensors - Analog and Digital Output - Industrial

Temperature Sensors - Analog and Digital Output

Temperature Sensors - NTC Thermistors

Temperature Sensors - PTC Thermistors

Temperature Sensors - RTD (Resistance Temperature Detector)

Temperature Sensors - Thermocouples, Temperature Probes

Temperature Sensors - Thermostats - Mechanical - Industrial

Temperature Sensors - Thermostats - Mechanical

Temperature Sensors - Thermostats - Solid State

Proximity/Occupancy Sensors - Finished Units

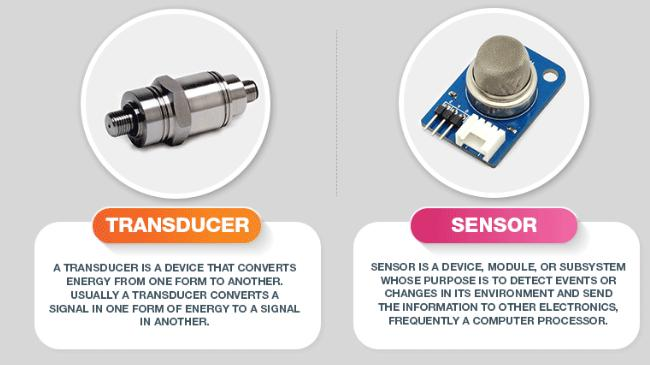

Sensor, transducer definition

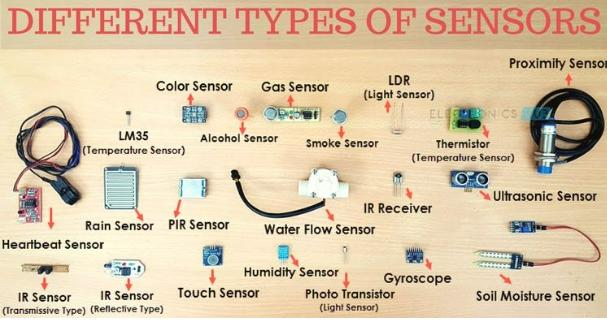

A sensor is a device or component that collects information from an object and converts it into a signal that a machine can process. Examples of sensors include temperature sensors, pressure sensors, ultrasonic sensors, light sensors, etc.

A transducer is an electronic device used to convert energy from one form to another. Examples of sensors include thermistors, potentiometers, piezoelectric sensors, and Hall effect sensors, among others.

What is the main difference between a sensor and a transducer?

The sensor is a device used to detect and measure environmental information, converting the information into electrical signals, while the transducer is the component within the sensor that is responsible for converting environmental information into the form of electrical signals. A sensor usually contains one or more transducers to carry out its function.

What are the main uses of sensors and transducers?

The primary purpose of sensors is to detect and measure physical quantities, conditions, or events in the environment to collect data for further processing and analysis.

The main purpose of a transducer is to convert one form of energy (such as sound, temperature, light) into another form of energy, usually an electrical signal, to achieve data collection and measurement.

What are the main functions of sensors and transducers?

The main function of sensors is to detect and measure various physical quantities, conditions or events in the environment and convert them into electrical signals or digital data for use in control, monitoring, measurement, communication and other applications.

The main function of a transducer is to convert one form of energy (such as sound, pressure, light, temperature, etc.) into another form of energy, usually an electrical signal, for data collection, measurement, and processing. In sensors, transducers are responsible for converting environmental information into the form of electrical signals for further processing by computers, control systems, or other devices.

A common example is a temperature sensor such as a thermistor. The main function of a temperature sensor is to measure the temperature in the environment and convert it into a change in resistance value.

This change in resistance can be measured by a circuit and converted into digital temperature data that is used to monitor and control temperature, such as in a thermostat, oven, or electronic thermometer. In this example, the function of the sensor is to detect temperature, and the function of the transducer is to convert the temperature information into a change in resistance value.

How many types of sensors are there?

A direct sensor is a sensor that can directly measure physical conditions (such as temperature, pressure, humidity, and motion) without the need for intermediate equipment, and usually outputs an electrical signal proportional to the physical quantity being measured. These sensors are widely used in fields such as industrial automation, robotics, and medical monitoring.

An indirect sensor is a device that indirectly measures a physical property through the use of an intermediate variable. They make use of different physical properties related to the physical property they want to measure, such as measuring temperature using a thermocouple, by measuring the voltage produced by the connection of two different metals, or measuring strain using a strain gauge, by measuring the resistance of a thin wire or metal foil. accomplish.

What are the different types of sensors?

A speed sensor is a position sensor used to measure rotational speed and is commonly found in a variety of commercial and motorsport vehicles.

A temperature sensor is a device used to detect and measure temperature and convert it into an electrical signal.

An ultrasonic sensor is a device that measures the distance of an object. It obtains distance information of an object by sending and receiving ultrasonic pulses.

Pyroelectric sensors exploit the surface charge generation of materials and are typically highly sensitive at room temperature and are used to detect external radiation.

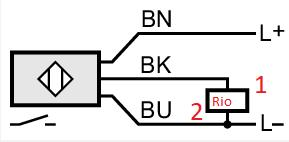

What are the 3 wires of the sensor?

A three-wire sensor consists of 3 wires: two power wires and one load wire. The power wire is used to connect to the power source, while the load wire is connected to the device controlled by the sensor. These sensors are used to control and monitor a variety of applications, and by connecting to power and load lines, they perform specific functions.

What are the pros and cons of sensors?

advantage:

High Accuracy: The sensor is capable of providing highly precise measurements, making it useful in applications in the scientific, medical, and engineering fields.

Automation and real-time feedback: Sensors can be used to achieve automated control and provide real-time data so that the system can respond quickly, improving production efficiency and convenience.

Remote monitoring: Sensors can be used for remote monitoring. For example, meteorological sensors can be used to monitor meteorological conditions in real time, which is crucial for disaster warning and meteorological research.

shortcoming:

Cost: High-precision sensors are typically more expensive, which may limit their use in some applications.

Complexity: Some sensors require complex installation and calibration, requiring specialized knowledge and increasing the difficulty of deployment and maintenance.

Maintenance and limited life: Sensors require regular maintenance and calibration, and they often have a limited life and require periodic replacement, which increases operating costs.

There are 3 main types of transducers

chemical transducer

A chemical transducer is a sensor that converts chemical signals into electrical signals and is used to measure chemical parameters such as pH, oxygen concentration, and carbon dioxide concentration.

Piezoelectric transducer

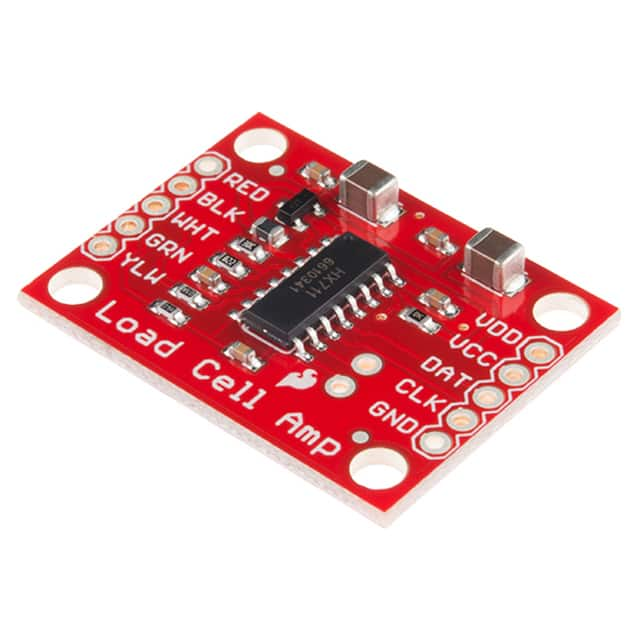

A piezoelectric transducer is an electromechanical device that converts electrical signals into mechanical vibrations and vice versa. They are widely used in fields such as medical imaging, robotics, audio systems, and pressure, force, and acceleration measurements.

Mutual induction sensor.

Mutual induction sensors use the principle of mutual inductance to convert electrical energy and mechanical energy into each other, and are usually used to measure displacement, force and pressure. They measure input signals by inducing magnetic fields and are low-cost, easy to use and simple to maintain.

Are transducers and sensors the same thing?

Both sensors and transducers are used to detect changes in the surrounding environment or within an object. However, the output provided by the sensor is usually in the same physical form, while the transducer converts the measurement into an electrical signal or other different forms of energy for further processing or transmission.

Can a device be both a sensor and a transducer?

Yes, some devices can serve dual functions as both sensors and transducers. These devices are able to detect changes in some physical or chemical parameter and then convert these changes into electrical signals or other forms of energy output.

For example, a temperature sensor can detect a change in temperature and convert it into a voltage signal, so it is both a sensor and a transducer in this case.

This dual-function device is commonly used in a variety of automation, monitoring, and control systems to measure and translate information about the environment or process. This comprehensive design simplifies system complexity and reduces the number of components required.

My Cart

My Cart