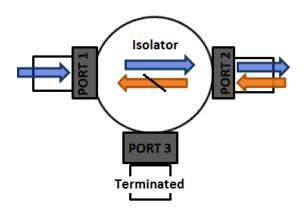

Isolator definition

An isolator is an electronic device used to physically separate electrical signals between circuits or electronic components to prevent the transfer of current, voltage, or noise.

This isolation is usually achieved through the use of insulating materials, magnetic materials, optical technology, or other isolation means. Isolators are commonly used in electrical safety, noise suppression, ground isolation, and circuit interconnection applications.

What is an isolator made of?

Isolator manufacturing materials and techniques vary depending on their type and purpose.

They can include optical elements, magnetic materials, capacitive elements, semiconductor materials, insulating materials, etc. These materials and technologies are used to physically isolate circuits or electronic components to increase circuit safety and reliability while meeting specific application needs.

The specific function of the isolator

The main function of an isolator is to physically isolate electrical signals between circuits or electronic components to improve circuit safety, anti-interference and reliability.

Applications include, but are not limited to, electrical safety, noise suppression, ground isolation, long-distance signal transmission, battery isolation, medical equipment and communications to ensure the proper operation of circuits and systems.

How does an isolator work?

The working principle of an isolator is based on electrical insulation, i.e. preventing the flow of direct current or voltage between two points. It uses insulating materials or devices, such as transformers, to prevent the passage of electricity between two points.

In addition, isolators can also be used as circuit breakers to interrupt the flow of electricity when necessary, preventing current overloads and other potentially dangerous conditions. This working principle helps improve the safety and reliability of the circuit.

Isolator type

Uses optical principles, such as photodiodes and light-emitting diodes, to separate input and output circuits to isolate electrical signals. Commonly used in digital isolation and communications applications.

Magnetic Isolator: Uses magnetic components, such as transformers, to separate input and output circuits to achieve electrical isolation. Typically used in power supply and high voltage applications.

Capacitive Isolator: Uses a capacitive element to prevent the transmission of electrical current, usually constructed of insulating materials, used in low- and mid-frequency applications.

Sensor isolator: used to isolate the signal between the sensor and the control circuit to prevent signal interference and improve measurement accuracy.

High Frequency Isolators: Specifically designed to isolate high frequency signals in applications such as radio frequency (RF) communications and antenna connections.

Digital isolator: used for the isolation of digital signals, usually including digital isolator chips, used in industrial control and communications.

Analog Isolator: Used for the isolation of analog signals, including analog signal isolation amplifiers, typically used in measurement and instrumentation applications.

Medical Isolators: Specifically designed for use in medical equipment to ensure electrical safety between the patient and the equipment.

Power isolator: used in power systems, including high-voltage insulating transformers, for power transmission and distribution.

Advantages and disadvantages of isolators

Advantage:

Electrical safety: Isolators improve the safety of electrical circuits by preventing current from flowing between different circuits, reducing the risk of electric shock and fire.

Noise isolation: Isolators can effectively isolate noise and ensure signal accuracy and stability, especially in noisy environments.

Ground wire isolation: used to isolate different ground wires, reduce ground wire interference and current loops, and improve circuit performance.

Signal transmission: In long-distance signal transmission, isolators can protect the signal from electrical interference and ensure signal quality.

Battery isolation: used to isolate the battery circuit and charging circuit to ensure charging safety.

Medical Safety: In medical equipment, isolators ensure electrical safety between the patient and the equipment.

Power system: Power isolators are used in power systems to ensure safe isolation between high-voltage circuits and low-voltage circuits.

Shortcoming:

Cost: The cost of isolators is relatively high, especially those with high performance or special applications.

Size and weight: Some isolators may require larger physical space and additional weight, especially in high voltage or high power applications.

Complexity: Installing and maintaining isolators may require additional engineering and complexity to ensure proper functionality.

Energy efficiency: Some isolators may introduce certain energy losses during signal transmission, especially in high-frequency applications.

Examples of different materials used in isolators

Insulating materials such as plastics, ceramics and glass are used to prevent current propagation, magnetic materials such as iron cores are used in magnetic isolators, semiconductor materials such as silicon are used in optical isolators and optical couplers, and metals are used in the electrodes and conductive layers of capacitive isolators. Semiconductor materials are used in the manufacture of photodiodes and light-emitting diodes to achieve optical isolation.

For example, a common type of isolator is an optocoupler, in which optical elements and semiconductor materials are combined to allow isolation of optical signals between circuits to prevent the flow of electrical current.

How to identify high-quality isolator materials?

Excellent isolator materials should have multiple properties: not only must they be able to effectively isolate current and voltage to ensure safe separation between circuits, but they must also have excellent heat resistance to maintain material stability in high-temperature environments. Dealing with extreme working conditions.

In addition, these materials should have excellent chemical stability and be resistant to a variety of corrosive chemicals to ensure problem-free long-term use. In optical isolators, materials also need to have good optical transparency to ensure efficient transmission of optical signals.

At the same time, the isolator material needs to be strong enough to withstand physical damage and mechanical stress to ensure the durability of the isolator. Finally, low capacitance is a key factor to reduce mutual capacitance and interference between circuits. The combined consideration of all these characteristics will ensure that the most suitable isolator material is selected for a specific application.

My Cart

My Cart